YDQ liquid resistance rotor starter

YDQ general introduction

1. General

1.1 product introduction

YDQ6 Liquid Resistance Rotor Starter (hereinafter referred to as starters) are the new kind of starting devices developed for improving the starting feature of large- and medium sized wire-wound AC asynchronous motors. Having solved the problems of frequency sensitive resistor starters which are high in impact current, difficult in starting and not easy to operate.

1.2 application range

the starters of this series are suitable for the heavy-load starting of the motors of ball grinding mills, air compressors, crushers, large-sized blast fans and large-sized pumps which are used in the industrial branches of building materials, metallurgy, chemical industry, mining. They are the ideal substitutes for frequency sensitive starters and metal resistor starters.

1.3 performance features

1.3.1 The starting current is low but constant without impact on power network; the starting current is no more than 1.3 times the rated current. Therefore the requirements of the heavy-load starting of motor for transformer capacity can be decreased, reducing lump sum investment.

1.3.2 It is smooth in starting, so as to lower its impact on the mechanical equipment, and the service life of the mechanical equipment and motor can be prolonged by about 30 percent.

1.3.3 It is high in its heat capacity, and it can start for 2~5 times continuously.

1.3.4 It can still start under low voltage state. Smooth start can be ensured so long as the voltage of the power network can guarantee the motor to operate normally.

1.3.5 It is simple in structure, easy to maintain. Its reliability is more superior than that of frequency sensitive, oil-soaked type resistors.

2. Technical parameters

2.1 working principle

Allow the relative distance between the two parallel plates in the conductive liquid to decrease progressively up to zero through a mechanical driving device and make the resistance value run into the return circuit of motor rotor decrease continuously, so as to realize the heavy-load smooth starting of large- and medium-sized wire-wound motors.

2.2 main technical parameters

|

Item |

standard |

remark |

|

Using standard |

Q/XDL J01-001—2015 |

|

|

Installation |

Indoor |

Outdoor available, please specify before ordering |

|

Applicable motor type |

Winding asynchronous motor |

|

|

Ambient temperature |

-5℃~45℃ |

Can customize for special conditions |

|

Altitude |

<1000 meters |

Can customize for special conditions |

|

Control power supply |

3 phase 4 line AC380V capacity 2kVA |

Please specify other type power supply if necessary |

|

Protection grade |

≥IP30 |

Maximum IP54, please specify before ordering |

|

Cooling method |

Air cooling |

|

|

Outgoing signal features |

Signal interlock with primary cabinet and DCS |

Switch value, for special requirements the DCS can adopt RS485 communication |

|

HV LV connection method |

Cable |

|

3. Service conditions

Upper limit of ambient temperature is +50℃, and lower limit is -5℃.

The relative humidity is no more than 85 percent. The altitude is no more than 2000m.

It should be placed on an indoor place without obvious shake and impact, without fire and explosive dangers and the vertical gradient is no more than 5º.

There must be no conductive dust and corrosive gas.

Power source is four-wire three-phase system of 380V/220V 20A, the undulation of voltage must be guaranteed within 15 percent of rated voltage.

Note:1)The heater needs to be installed additionally when the ambient temperature is under 0℃ over a long period of time, the user should explain it while ordering goods.

2)If the voltage of power source needs special design, the user should explain it while ordering goods.

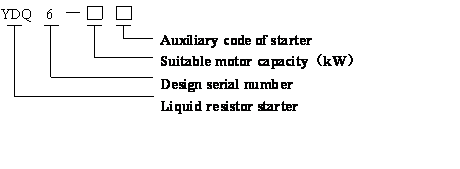

4. Type select

4.1 type explanation

Auxiliary function code:

K Equipped with low voltage motor primary circuit

B Equipped with vacuum contactor

PC Using programmable controller

Various added codes can be combined to finish relevant functions。Only 0.2-0.4 series can be equipped with low voltage motor primary circuit, and the heater needs to be installed additionally when the ambient temperature is under 0℃ over a long period of time, PLC also can be adopted according with requirements.

The auxiliary code can be combined used. For site which is long-term under 0℃ electrical heating function will be added.

4.2 external dimensions

|

Type |

Suitable motor capacity(KW) |

Starting time(S) |

The number of consecutive start |

Remark |

||

|

Light load temperature rise ≤5 ℃ per start |

Heavy load temperature rise ≤10 ℃ per start |

Light load temperature rise ≤5 ℃ per start |

Heavy load temperature rise ≤10 ℃ per start |

|

||

|

YDQ6-0.4 |

≤400 |

15~25 |

25~35 |

5~10 |

3~5 |

|

|

YDQ6-0.6 |

≤600 |

|||||

|

YDQ6-1 |

≤1000 |

|||||

|

YDQ6-2 |

≤2000 |

|||||

|

YDQ6-3 |

≤3000 |

|||||

|

YDQ6-4 |

≤4000 |

|||||

|

YDQ6-6 |

≤6000 |

|||||

Remarks:

4.2.1 structure of soft starter for larger motor can be customized according to user’s requirements

4.2.2 light load: mill, roller press, rolling mill, compressor and etc.

Heavy load: fan, crusher and etc.

4.2.3 for different load type, the moment of inertia is different. The starting time and temperature rise is also different.

4.2.4 start times is relative to liquid original temperature and alarm temperature. Start times = (alarm temperature - original temperature) / temperature rise per start

5. Ordering instructions

Please provide following information to Big Pawer before ordering

5.1 selected soft starter type

5.2 motor power, stator voltage, stator current, rotor voltage, rotor current

5.3 load type

5.4 cabinet color (company standard or specified)

5.5 short-circuit contactor or circuit breaker (company standard or specified).