HVFS High voltage frequency-converting soft starter

High voltage frequency converting soft starter

Introduction

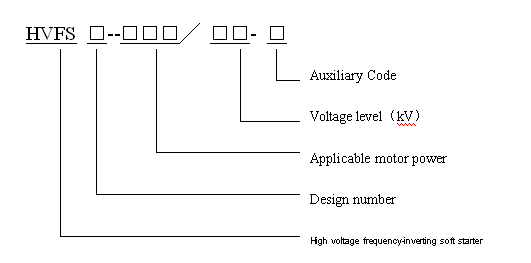

Type demonstration

Note:

Voltage level: 06--6KV, 10--10KV

Auxiliary Code: L--Light load, H--Heavy load, default light load

Example:

HVFS1-5000/06-L

means HVFS high voltage frequency converting soft start device is applicable to the motor with 5000KW capacity and 6KV rated voltage light load start

Features:

1.Soft start function: Starting current less than rated current, repeatedly start allowed.

2.Direct high voltage in-out power distribution: DLHVF high frequency-converting speed regulator is appicable for normal AC induction motor. It directly input and output high voltage electric power. No transformer is needed. The device occupies little area.

3.No harmonic input: HVFS device has utilized the phase shift multi-rectify technology, the voltage and current harmonic is low. There is no need to use harmonic control devices in the input progress, no pollution to power system.

4.No harmonic output: HVFS device output standard sine waves, the voltage and current harmonic is low. No harmonic control device is needed in output progress. It will not increase the motor noise and will not generate additional stress.

5.High security level: HVFS is designed following China high voltage peremptory norm, high voltage primary circuit and control circuit are connected by optical fiber.

6.Perfect protection and fault alarm design: HVFS has perfect system protection and power unit protection function. And after protection it will auto record and simulate the fault conditions. The fault record includes protection operations, starting and lasting time which can help the analysis and define of fault.

7.Great flexibility: HVFC device is real-time controlled by PLC(programmable Logic controller) . The control type settings can be convenient changed in human-computer interface. Variable standard communication protocol convenient for communication with center-control system.

8.Convenient installation, commission and maintenance: Drawer-type power unit, connect assembly for power unit and external wire. No manual connection needed and convenient to replace.

Unique features:

1.Waveform digitization direct synthesis adaptive technology:

HVFS Wavegenerator utilizes single-chip FPGA with certain algorithm to obtain discretization frequency and controllable amplitude 3-phase wave status, then compare to delta carrier in different phase and generates wave digital signal to control the power units in same phase to output fundamental wave in same amplitude and phase. The electric angle of carrier which connects every unit is staggered to implement multilevel superimposed waveforms and greatly enhance the reliability of the control system.

a)Low voltage overall commission function:

HVFS can utilize low voltage control power to do high voltage frequency-converting soft start function test. User can commission and maintain the device without high voltage power or frequency-converting. Therefore the commission and maintenance time is significantly reduced.

2.Advanced fault self check technology

HVFS device will online check all system and every power unit before starting. The check can be detailed to status of each IGBT chips, so that it can assure the device is in good condition and make the preparation more smooth.

3.Drawer-type power unit, convenient to replace and maintain:

Power units in HVFS device are connected with main circuit by active and static contactor. In installation and cannibalization progress only two optical fibers need to be removed. No need to install and remove the screws in main circuit. Besides, all the main circuit is contacted in cabinet, assures the safe of operators.

4.Power unit DC voltage online test function:

HVFS will online check the DC bus voltage of each power unit and shows the measurement results in human-computer interface, so that operator can easily realize the working condition of each power unit’s main circuit and progress detailed analysis.

5.Frequency-converting soft start technology

The starting current is very low in frequency-convering starting progress. No limit of starting times. After starting the frequency of motor will be back to 50Hz. No current impulse in starting progress.

6.Frequency converting synchronous switching technology (Optional)

An electric reactor cabinet will be added in frequency converting starter output, when the frequency converting starting progress is over and the frequency changes to 50Hz the frequency converting synchronous switching technology will be utilized. No current impulse generated in switching progress. Especially applicable to large or medium motor frequency converting start.

7.Dedicated frequency converting soft start digital synchronous device

The digital synchronous device is customized for frequency converting synchronous switching technology. It can monitor the frequency converting synchronous switching progress independently. When synchronized-grid connection is possible it will output synchronous admit signal to assure that switching progress will not cause problem because fault operation of frequency converting soft start device.

Outside dimension

|

HVFS Type |

Rated voltage |

Capacity of motor |

Measurement |

|

HVFS-1000/06 |

6kV |

1000kW |

3600*2300*1200 |

|

HVFS-2000/06 |

6kV |

2000kW |

3600*2300*1200 |

|

HVFS-3000/06 |

6kV |

3000kW |

3600*2300*1200 |

|

HVFS-4000/06 |

6kV |

4000kW |

3800*2300*1300 |

|

HVFS-5000/06 |

6kV |

5000kW |

3800*2300*1300 |

|

HVFS-6000/06 |

6kV |

6000kW |

4100*2300*1300 |

|

HVFS-7000/06 |

6kV |

7000kW |

4100*2300*1300 |

|

HVFS-8000/06 |

6kV |

8000kW |

4400*2300*1400 |

|

HVFS-9000/06 |

6kV |

9000kW |

4400*2300*1400 |

|

HVFS-1000/10 |

10kV |

1000kW |

4200*2300*1200 |

|

HVFS-2000/10 |

10kV |

2000kW |

4200*2300*1200 |

|

HVFS-3000/10 |

10kV |

3000kW |

4200*2300*1200 |

|

HVFS-4000/10 |

10kV |

4000kW |

4200*2300*1200 |

|

HVFS-5000/10 |

10kV |

5000kW |

4200*2300*1200 |

|

HVFS-6000/10 |

10kV |

6000kW |

4500*2300*1200 |

|

HVFS-7000/10 |

10kV |

7000kW |

4800*2300*1300 |

|

HVFS-8000/10 |

10kV |

8000kW |

4800*2300*1300 |

|

HVFS-9000/10 |

10kV |

9000kW |

4800*2300*1300 |

|

HVFS-10000/10 |

10kV |

10000kW |

4800*2300*1300 |

|

HVFS-15000/10 |

10kV |

15000kW |

5400*2400*1400 |

|

HVFS-20000/10 |

10kV |

20000kW |

5700*2400*1400 |

|

HVFS-25000/10 |

10kV |

25000kW |

6000*2400*1400 |

|

HVFS-30000/10 |

10kV |

30000kW |

6300*2500*1500 |

|

HVFS-40000/10 |

10kV |

40000kW |

6900*2500*1500 |

|

HVFS-50000/10 |

10kV |

50000kW |

7500*2500*1600 |

|

HVFS-60000/10 |

10kV |

60000kW |

8100*2500*1700 |

Note:

1.The dimension includes phase shifting transformer cabinet, power unit cabinet and control cabinet, does not include power frequency switch cabinet and electric reactor cabinet(optional frequency converting synchronous switching function). The height does not include base channel steel (100mm) at the bottom and cooling fan (286~361mm) at the top.

2.Frequency converting soft start has two functions: synchronous and asynchronous switching. We advice that motor with no more than 10,000 KW capacity should be started with asynchronous function. Motor with more than 10,000 KW capacity should be started with synchronous function, and a electric reactor cabinet is needed.

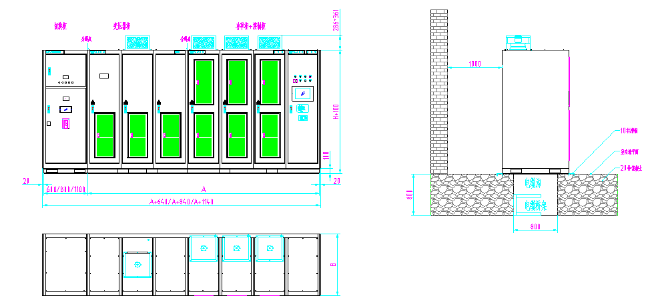

3.In asynchronous mode, the layout will be power frequency switch cabinet + transformer cabinet + power unit cabinet + control cabinet. The shape and installation refers to Picture 1 below.

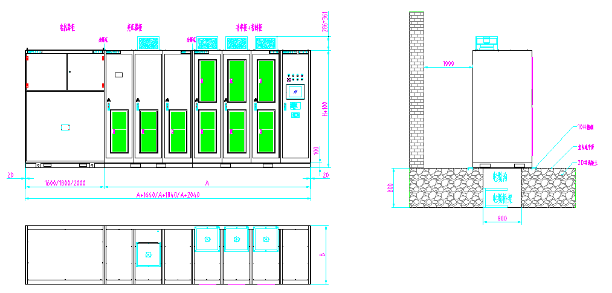

In synchronous mode, the layout will be power frequency switch cabinet + electric reactor cabinet + transformer cabinet + power unit cabinet + control cabinet, The shape and installation refers to Picture 2 below.

Pic 1

Pic 2

4.When vacuum contactor is used in power frequency switch cabinet, the width of 6KV switch cabinet is 600mm and 10KV switch cabinet is 800mm. When vacuum circuit breaker is used, the width of switch cabinet is 1100mm; when independent high voltage cabinet is used, the dimension depends on the high voltage cabinet.

The dimension of electric reactor cabinet depends on the capacity of device, the width is between 800mm to 2000mm.

5.No special inform if the dimension is changed, detailed dimension is decided in technology agreement.

Working principles

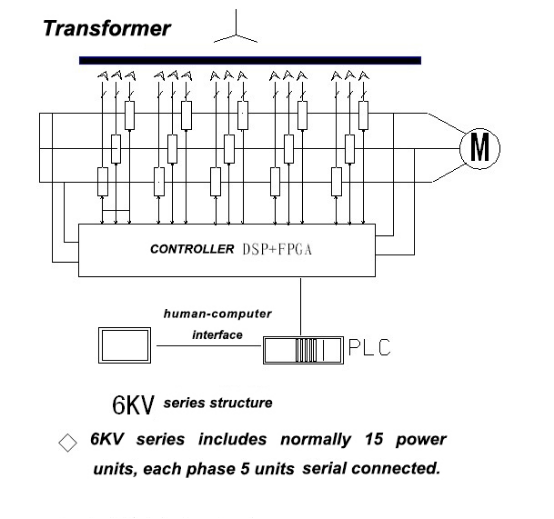

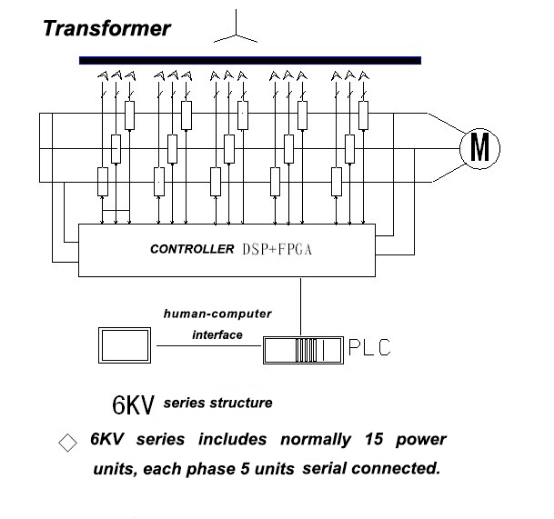

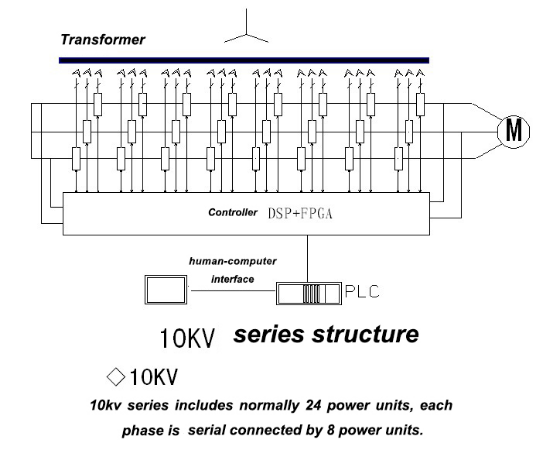

Pic 3: HVFS series device topological diagram

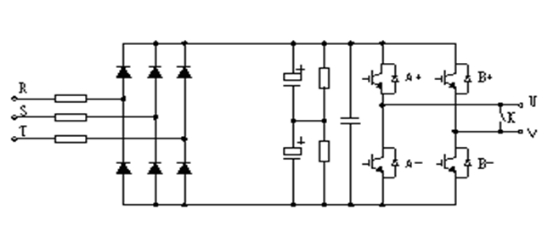

Pic 4: Chematic diagram of typical power unit

Main Circuit

HVFS series device stacks the output of low voltage power units to obtain high voltage. Low voltage power units are optimized and enhanced standard low voltage PWM( Pulse Width Modulation) motor frequency converter, which has been widely utilized for many years. The upper HVFS series device topological diagram shows in 6KV HVFS device each phase of motor is driven by 3~6 serial connected power units, altogether 9~18 power units can generate 4000~7000V AC voltage. In 10KV HVFS device each phase of motor is driven by 6~9 serial connected power units, altogether 18~27 power units can generate 7000~11000V AC voltage. The power units are serial star-connected, the neutral line is floated. Each power unit is feeded by isolating secondary winding of an isolating transformer, input 3-phase 710V AC, 50/60Hz power source. Inverter output maximum voltage 750V AC, maximum frequency 60Hz variable power source. Power units and corresponding transformer secondary winding and insulation grade against groud are designed for corresponding 6KV and 10KV high voltage grade.

All power units receive the command from the same main control unit controller. These commands are transported via optical fiber to assure the insulation between high and low voltage.