TBB(A) series type high voltage parallel capacitor device

1. General

1.1 Brief introduction

TBB series type high voltage parallel capacitor device has indoor cabinet type and outdoor frame type structure. With its reasonable design and layout it has good kinetic and heat stability and capacitor protection functions. According to the system condition of users, electric reactor with different reactance rate can be equipped to suppress harmonic and switching in rush current, to restrict the instant rush current generated when the capacitor is put into operation to less than 20 times rated current of capacitor bank.

1.2 Application range

TBB series type high voltage parallel capacitor device is suitable for 50Hz power distribution system with rated voltage 6kV/10kV/35kV as compensation device of system reactive power.

1.3 Technical feature

The product can adjust adjust the power factor of power distribution system to maximum, adjust the grid voltage to reduce the loss of power distribution system and transformer, further to improve the power quality of power grid.

2. Technical parameter

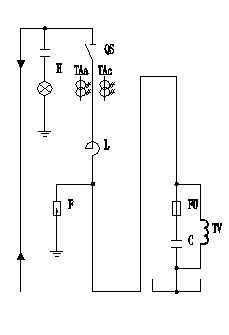

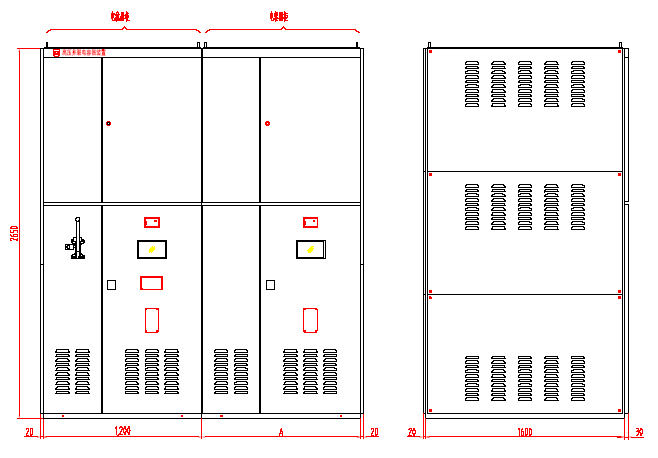

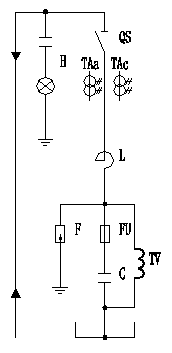

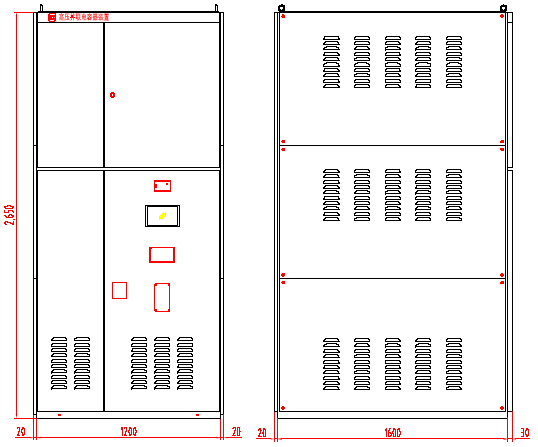

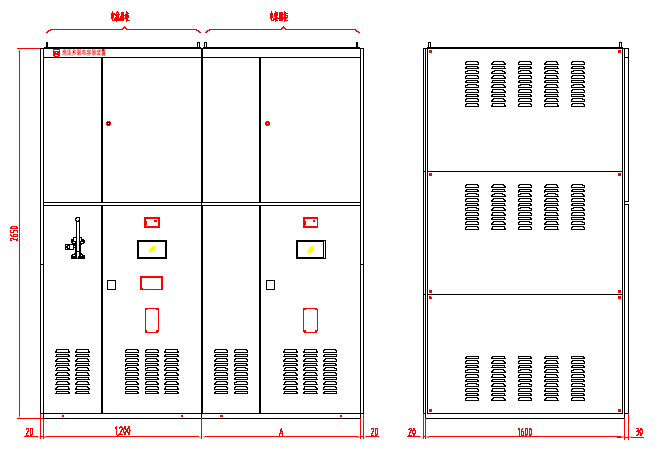

Diagrams 1, 2, 3 are typical primary system diagram and outside diagram; Tables 1, 2, 3 are corresponding type, specifications, main parameters and external dimensions.

External and installation dimensions are subject to detailed design.

Diagram 1(scheme 1): primary system and outside diagram (HV capacitor switch cabinet chosen by user)

Diagram 2(scheme 2): primary system diagram and outside diagram(HV capacitor switch cabinet chosen by user)

Diagram 3(scheme 3): primary system diagram and outside diagram(HV capacitor switch cabinet chosen by user)

Table 1 (scheme 1)

|

Type |

Rated voltage (kv) |

Capacitor bank rated capacity (kvar) |

Device rated current (A) |

Wiring type |

External dimensions Width (1200mm+A)×depth×height (mm) |

|

TBB6-900/300-AK |

6 |

900(3×300) |

78.7 |

Y |

2400×1600×2650 |

|

TBB6-1000/334-AK |

6 |

1000(3×334) |

87.4 |

Y |

2400×1600×2650 |

|

TBB6-1200/200-AK |

6 |

1200(6×200) |

105 |

Y |

2400×1600×2650 |

|

TBB6-1500/250-AK |

6 |

1500(6×250) |

131 |

Y |

2400×1600×2650 |

|

TBB6-1800/300-AK |

6 |

1800(6×300) |

157.5 |

Y |

2400×1600×2650 |

|

TBB6-2000/334-AK |

6 |

2000(6×334) |

175 |

Y |

2400×1600×2650 |

|

TBB10-900/300-AK |

10 |

900(3×300) |

47 |

Y |

2400×1600×2650 |

|

TBB10-1000/334-AK |

10 |

1000(3×334) |

52.5 |

Y |

2400×1600×2650 |

|

TBB10-1200/400-AK |

10 |

1200(3×400) |

63 |

Y |

2400×1600×2650 |

|

TBB10-1500/500-AK |

10 |

1500(3×500) |

78.7 |

Y |

2400×1600×2650 |

|

TBB10-1800/300-AK |

10 |

1800(6×300) |

94.5 |

Y |

2400×1600×2650 |

|

TBB10-2000/334-AK |

10 |

2000(6×334) |

105 |

Y |

2400×1600×2650 |

|

TBB10-2400/400-AK |

10 |

2400(6×400) |

126 |

Y |

2400×1600×2650 |

|

TBB10-2700/450-AK |

10 |

2700(6×450) |

141.7 |

Y |

2400×1600×2650 |

|

TBB10-3000/500-AK |

10 |

3000(6×500) |

157.5 |

Y |

2400×1600×2650 |

Table 2(scheme 2)

|

Type |

Rated voltage (kv) |

Capacitor bank rated capacity (kvar) |

Device rated current (A) |

Wiring type |

External dimensions Width×depth×height (mm) |

|

TBB6-300/100-AK |

6 |

300(3×100) |

26 |

Y |

1200×1600×2650 |

|

TBB6-450/150-AK |

6 |

450(3×150) |

39.4 |

Y |

1200×1600×2650 |

|

TBB6-600/200-AK |

6 |

600(3×200) |

52.5 |

Y |

1200×1600×2650 |

|

TBB6-750/250-AK |

6 |

750(3×250) |

65.6 |

Y |

1200×1600×2650 |

|

TBB6-900/300-AK |

6 |

900(3×300) |

78.7 |

Y |

1200×1600×2650 |

|

TBB6-1000/334-AK |

6 |

1000(3×334) |

87.5 |

Y |

1200×1600×2650 |

|

TBB10-300/100-AK |

10 |

300(3×100) |

15.7 |

Y |

1200×1600×2650 |

|

TBB10-450/150-AK |

10 |

450(3×150) |

23.6 |

Y |

1200×1600< |

Table 3(scheme 3)

|

Type |

Rated voltage (kv) |

Capacitor bank rated capacity (kvar) |

Device rated current (A) |

Wiring type |

External dimensions Width (1200mm+A)×depth×height (mm) |

|

TBB6-1800/300-BL |

6 |

1800(6×300) |

157.5 |

Y-Y |

2400×1600×2650 |

|

TBB6-2000/334-BL |

6 |

2000(6×334) |

175 |

Y-Y |

2400×1600×2650 |

|

TBB6-2400/200-BL |

6 |

2400(12×200) |

210 |

Y-Y |

3600×1600×2650 |

|

TBB6-3000/250-BL |

6 |

3000(12×250) |

262.4 |

Y-Y |

3600×1600×2650 |

|

TBB6-3600/300-BL |

6 |

3600(12×300) |

315 |

Y-Y |

3600×1600×2650 |

|

TBB6-4000/334-BL |

6 |

4000(12×334) |

350 |

Y-Y |

3600×1600×2650 |

|

TBB6-4500/250-BL |

6 |

4500(18×250) |

393.6 |

Y-Y |

4800×1600×2650 |

|

TBB6-5400/300-BL |

6 |

5400(18×300) |

472.4 |

Y-Y |

4800×1600×2650 |

|

TBB6-6000/334-BL |

6 |

6000(18×334) |

525 |

Y-Y |

4800×1600×2650 |

|

TBB10-1800/300-BL |

10 |

1800(6×300) |

95 |

Y-Y |

2400×1600×2650 |

|

TBB10-2000/334-BL |

10 |

2000(6×334) |

105 |

Y-Y |

2400×1600×2650 |

|

TBB10-2400/400-BL |

10 |

2400(6×400) |

126 |

Y-Y |

2400×1600×2650 |

|

TBB10-3000/500-BL |

10 |

3000(6×500) |

157.5 |

Y-Y |

2400×1600×2650 |

|

TBB10-3600/300-BL |

10 |

3600(12×300) |

189 |

Y-Y |

3600×1600×2650 |

|

TBB10-4000/334-BL |

10 |

4000(12×334) |

210 |

Y-Y |

3600×1600×2650 |

|

TBB10-4800/400-BL |

10 |

4800(12×400) |

252 |

Y-Y |

3600×1600×2650 |

|

TBB10-5400/450-BL |

10 |

5400(12×450) |

283 |

Y-Y |

3600×1600×2650 |

|

TBB10-6000/500-BL |

10 |

6000(12×500) |

315 |

Y-Y |

3600×1600×2650 |

|

TBB10-7200/400-BL |

10 |

7200(18×400) |

378 |

Y-Y |

4800×1600×2650 |

|

TBB10-8100/450-BL |

10 |

8100(18×450) |

425 |

Y-Y |

4800×1600×2650 |

|

TBB10-9000/500-BL |

10 |

9000(18×500) |

472 |

Y-Y |

4800×1600×2650 |

3. Service conditions

There are indoor and outdoor types of the product;

Ambient temperature -25℃~+45℃;

Relative humidity maximum 85%;

Altitude maximum 1000m;

Installation place should avoid strenuous vibration;

The maximum horizontal gradient of installation should be 5 degree;

No harmful gas, vapor, electric or explosive gas and other dangerous materials;

Remark: If above-mentioned requirements can not be met, special design is needed.

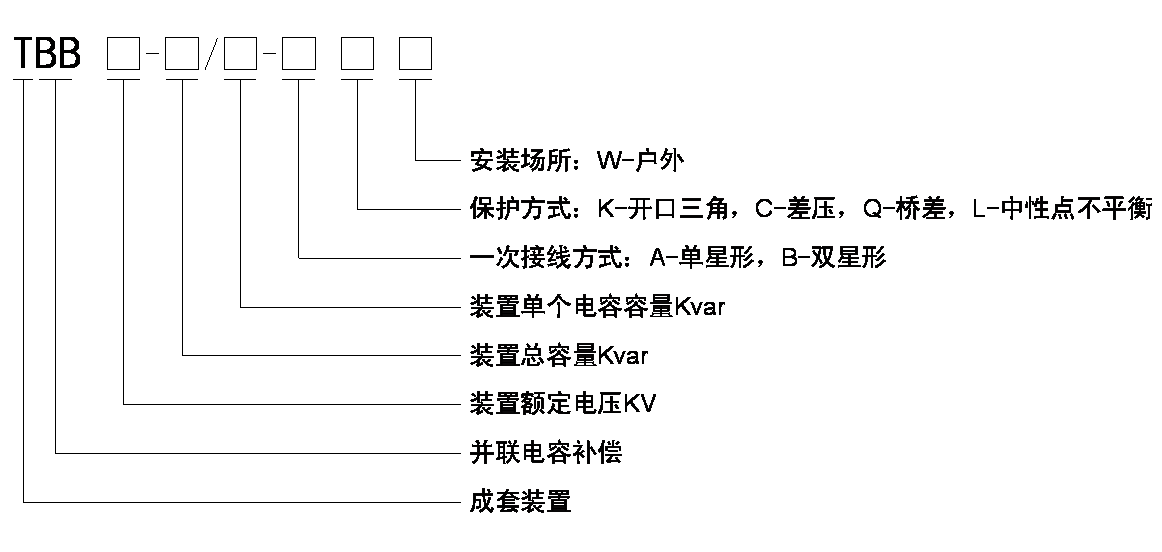

4. Type explanation

Installation: W-outdoor

Protection mode: K-open delta, C-voltage differential, Q-bridge differential, L-neutral point imbalance

Primary wiring type: A-single star, B-double star

Single capacitor capacity kVar

Total capacity kVar

Device rated voltage kV

Parallel capacitor compensation

Complete set

5. Ordering instructions

Following documents should be provided to manufacturer before ordering

Primary wiring diagram, floor diagram, layout diagram.

Type, specifications, voltage level, capacity, scheme type, incoming type of product.

Please specify if following components are required: serial connected reactor, zinc oxide arrester, discharge coil, earthing knife switch, complete set cabinet, enclosure and others.

Customized cabinet dimensions and color.

Other special technical requirements.